Sodium Hydroxide

- SODIUM HYDROXIDE

- 1310-73-2

- Caustic soda

- Sodium hydrate

- Aetznatron

- Create:2005-03-26

- Modify:2025-01-18

- Caustic Soda

- Hydroxide, Sodium

- Soda, Caustic

- Sodium Hydroxide

- SODIUM HYDROXIDE

- 1310-73-2

- Caustic soda

- Sodium hydrate

- Aetznatron

- Soda lye

- White caustic

- Ascarite

- Soda, caustic

- Natriumhydroxid

- Rohrputz

- Plung

- Liquid-plumr

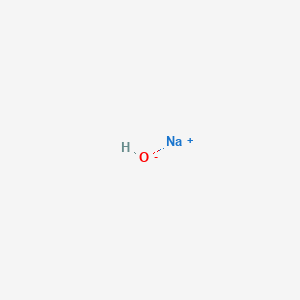

- Sodium hydroxide (Na(OH))

- Fuers Rohr

- Rohrreiniger Rofix

- NaOH

- Hydroxyde de sodium

- Natriumhydroxyde

- Collo-Grillrein

- Collo-Tapetta

- Soda, hydrate

- Sodium hydroxide dimer

- Ascarite II

- Natrium causticum

- Soda, kaustische

- Lewis-red devil lye

- Sodio(idrossido di)

- 81133-20-2

- Stamperprep

- Caustic soda, liquid

- Sodium(hydroxyde de)

- Caswell No. 773

- sodium;hydroxide

- Tosoh pearl

- Sodium hydroxide (Na2(OH)2)

- Sodium hydroxide, pellets

- Natrium-hydroxid, reinstes

- UN 1823 (solid)

- Promoter 3308b

- HSDB 229

- soude caustique

- Natrii hydroxydum

- EINECS 215-185-5

- LYE

- MFCD00003548

- EPA Pesticide Chemical Code 075603

- NSC 135799

- NSC-135799

- UNII-55X04QC32I

- CHEBI:32145

- INS-524

- 55X04QC32I

- Sodium hydroxide, flake

- Sodium hydroxide, solid

- DTXSID0029634

- E-524

- EC 215-185-5

- Sodium hydroxide; NaOH

- Na (O H)

- SODIUM HYDROXIDE (MART.)

- SODIUM HYDROXIDE [MART.]

- sodiumhydroxide

- Natriumhydroxid [German]

- Natriumhydroxyde [Dutch]

- Hydroxide, Sodium

- Hydroxyde de sodium [French]

- Sodio(idrossido di) [Italian]

- Sodium(hydroxyde de) [French]

- Sodium Hydroxide (0.1M in water (0.1N))

- Sodium hydroxide [NF]

- UN1823

- UN1824

- sodiumhydroxid

- hydroxyl sodium

- sodio hidroxido

- sodium hydoxide

- sodium hydroxid

- sodium hyroxide

- Soda asbestos

- hydroxide sodium

- Natrii hydroxidum

- Caustic soda, dry

- Caustic soda, bead

- Caustic soda, flake

- Caustic soda, solid

- Sodium(hydroxide de)

- Sodium hydroxide, dry

- Sodium hydroxide beads

- Caustic soda, granular

- Sodium hydroxide liquid

- Sodium hydroxide pearls

- Sodium hydroxide, bead

- Sodium hydroxide 50%

- Sodium hydroxide (TN)

- Sodium hydroxide, pearl

- Sodium hydroxide (flake)

- Sodium hydroxide (NaOH)

- Sodium hydroxide (liquid)

- Sodium hydroxide, granular

- WLN: NA Q

- Sodium hydroxide, anhydrous

- Caustic Soda, Dry (DOT)

- Caustic Soda, Bead (DOT)

- Caustic Soda, Flake (DOT)

- Caustic Soda, Solid (DOT)

- Sodium hydroxide pellets, EP

- Sodium hydroxide, micropearls

- SODIUM HYDROXIDE [II]

- SODIUM HYDROXIDE [MI]

- Sodium hydroxide (JP17/NF)

- SODIUM HYDROXIDE [FCC]

- SODIUM HYDROXIDE [JAN]

- Sodium Hydroxide, Dry (DOT)

- Caustic Soda, Granular (DOT)

- DTXCID609634

- Sodium Hydroxide, Bead (DOT)

- SODIUM HYDROXIDE [HSDB]

- CHEMBL2105794

- SODIUM HYDROXIDE [VANDF]

- Sodium Hydroxide, Flake (DOT)

- Sodium Hydroxide, Solid (DOT)

- Sodium hydroxide pellets USP-NF

- SODIUM HYDROXIDE [WHO-DD]

- SODIUM HYDROXIDE [WHO-IP]

- Sodium Hydroxide, Granular (DOT)

- BCP26108

- NSC135799

- Sodium hydroxide pellets ACS reagent

- AKOS015913904

- AKOS015951419

- DB11151

- SODIUM HYDROXIDE [EP MONOGRAPH]

- USEPA/OPP Pesticide Code: 075603

- NATRII HYDROXYDUM [WHO-IP LATIN]

- Sodium hydroxide pellets Biochemical Grade

- NS00076150

- O0575

- S0543

- Sodium azidodifluoroacetate 0.25 M in water

- Sodium hydroxide 10% aqueous solution (wt/v)

- Sodium hydroxide, ROTI?Volum, 1N (Ampoule)

- D01169

- Sodium hydroxide, solid [UN1823] [Corrosive]

- Q102769

- J-005935

- Sodium hydroxide, pellets, Trace Metals Grade 99.99%

- 1.25N NaOH Distillation Fluid, 50 x 10 mL, smart delivery PFA Tube

- nuclear quadrupole moment

- dielectric constant

- nuclear quadrupole coupling

- crystal structure

- diffusion

- enthalpy

- isothermal section

- molar conductivity

- Gibbs energy

- positional coordinate

- temperature-composition section

- electron conductivity

- space group

- molecular structure

- enthalpy change

- light scattering

- phase diagram

- unit cell parameter

- lattice distortion

- melting temperature

- heat capacity

- Schoenflies notation

- sound velocity

- excitation energy

- transition enthalpy

- electric dipole moment

- displacement parameter

- internuclear distance

- structural transition temperature

- sound propagation

- transport data

- sound absorption

- phase transition

- rotational excitation cross section

- chemical diffusion

- elastic stiffness

- formation entropy

- elastic coefficients

- X-ray diffraction

- ionic conductivity

- atomic environment

- quadrupole coupling

- transition entropy

- formation enthalpy

- corrosion

- density

- temperature parameter

- molar heat capacity

- diamagnetic susceptibility

- formation energy

- nuclear quadrupole resonance spectroscopy

- unit cell axes

- chemical bond

- compressibility

- latent heat

- Raman data

- infrared spectroscopy

- elasticity

- entropy

- local structure

- Raman spectroscopy

- neutron diffraction

- point group

- viscosity

- nuclear magnetic resonance

- diffusive flux

- spin-lattice relaxation

Acid and Alkali Cleaning of Metals [Category: Clean]

Electroplating [Category: Plate]

Petroleum Production and Refining [Category: Industry]

Semiconductor Manufacturing [Category: Industry]

Smelting Copper or Lead [Category: Industry]

Textiles (Fiber & Fabric Manufacturing) [Category: Industry]

Leather Tanning and Processing [Category: Industry]

Photographic Processing [Category: Other]

Textiles (Printing, Dyeing, or Finishing) [Category: Industry]

Metal Extraction and Refining [Category: Industry]

Textile arts [Category: Hobbies]

Applying metallic patinas [Category: Hobbies]

Green circle - The chemical has been verified to be of low concern

Green circle - The chemical has been verified to be of low concern- Density modifier

- Laboratory chemicals

- Other (specify)

- Solvents (for cleaning or degreasing)

- Solvents (which become part of product formulation or mixture)

- Plasticizers

- Oxidizing/reducing agents

- Ion exchange agent

- Not Known or Reasonably Ascertainable

- Adsorbents and absorbents

- Intermediate

- Solvent

- Sealant (barrier)

- Corrosion inhibitors and anti-scaling agents

- Stabilizing agent

- Fuels and fuel additives

- Thickening agent

- Anti-scaling agent

- Intermediates

- Bleaching agents

- Adhesives and sealant chemicals

- Processing aids, specific to petroleum production

- Process regulators

- Processing aids not otherwise specified

- Finishing agents

- Corrosion inhibitor

- Abrasives

- Diluent

- Leaching agent

- Sizing agent

- Ion exchange agents

- Dye

- Other

- Bleaching agent

- Pigments

- Solids separation agents

- Anti-adhesive agents

- Flotation agent

- Cleaning agent

- pH regulating agent

- Plasticizer

- Swelling agent

- Odor agents

- Surface active agents

- Plating agents and surface treating agents

- Processing aids, not otherwise listed

- Agricultural chemicals (non-pesticidal)

- Paint additives and coating additives not described by other categories

- Catalyst

- Softener and conditioner

- Viscosity adjustors

- Bleaching agent

- Other

- Pigments

- Processing aids, specific to petroleum production

- Process regulators

- Processing aids not otherwise specified

- Finishing agents

- Corrosion inhibitor

- Brightener

- Plating agents and surface treating agents

- Processing aids, not otherwise listed

- Softener and conditioner

- Paint additives and coating additives not described by other categories

- Agricultural chemicals (non-pesticidal)

- Solids separation agents

- pH regulating agent

- Cleaning agent

- Oxidizing agent

- Ion exchange agent

- Oxidizing/reducing agents

- Plasticizers

- Laboratory chemicals

- Solvents (for cleaning or degreasing)

- Other (specify)

- Fuels and fuel additives

- Intermediates

- Adhesives and sealant chemicals

- Bleaching agents

- Adsorbents and absorbents

- Not Known or Reasonably Ascertainable

- Intermediate

- Solvent

- Sealant (barrier)

- Corrosion inhibitors and anti-scaling agents

Cosmetics product ingredient: Sodium hydroxide

Reason for Listing: Identified with non-cancer endpoints and listed with an inhalation or oral Reference Exposure Level by the California Office of Environmental Health Hazard Assessment under Health and Safety Code section 44360(b)(2)

Potential Health Impacts: Dermatotoxicity, Ocular Toxicity, and Respiratory Toxicity

Product count: 655

Information on 1896 consumer products that contain Sodium hydroxide in the following categories is provided:

• Auto Products

• Commercial / Institutional

• Home Maintenance

• Inside the Home

• Landscaping/Yard

• Personal Care

• Pesticides

• Pet Care

2019: 20,000,000,000 - <30,000,000,000 lb

2018: 20,000,000,000 - <30,000,000,000 lb

2017: 20,000,000,000 - <30,000,000,000 lb

2016: 20,000,000,000 - <30,000,000,000 lb

- All other Petroleum and Coal Products Manufacturing

- Fabricated Metal Product Manufacturing

- Plastics Product Manufacturing

- Wood Product Manufacturing

- Synthetic Dye and Pigment Manufacturing

- Paper Manufacturing

- Utilities

- Plastics Material and Resin Manufacturing

- Not Known or Reasonably Ascertainable

- Petrochemical Manufacturing

- Soap, Cleaning Compound, and Toilet Preparation Manufacturing

- Synthetic Rubber Manufacturing

- Primary Metal Manufacturing

- Construction

- Oil and Gas Drilling, Extraction, and Support activities

- All Other Chemical Product and Preparation Manufacturing

- Textiles, apparel, and leather manufacturing

- Miscellaneous Manufacturing

- Wholesale and Retail Trade

- Organic Fiber Manufacturing

- Mining (except Oil and Gas) and support activities

- Food, beverage, and tobacco product manufacturing

- Petroleum Lubricating Oil and Grease Manufacturing

- Petroleum Refineries

- Other (requires additional information)

- All Other Basic Inorganic Chemical Manufacturing

- Pesticide, Fertilizer, and Other Agricultural Chemical Manufacturing

- All Other Basic Organic Chemical Manufacturing

- Agriculture, Forestry, Fishing and Hunting

- Paint and Coating Manufacturing

H290 (47.3%): May be corrosive to metals [Warning Corrosive to Metals]

H314 (> 99.9%): Causes severe skin burns and eye damage [Danger Skin corrosion/irritation]

H315 (36.5%): Causes skin irritation [Warning Skin corrosion/irritation]

H318 (43.8%): Causes serious eye damage [Danger Serious eye damage/eye irritation]

H319 (36.7%): Causes serious eye irritation [Warning Serious eye damage/eye irritation]

P234, P260, P264, P264+P265, P280, P301+P330+P331, P302+P352, P302+P361+P354, P304+P340, P305+P351+P338, P305+P354+P338, P316, P317, P321, P332+P317, P337+P317, P362+P364, P363, P390, P405, P406, and P501

(The corresponding statement to each P-code can be found at the GHS Classification page.)

Aggregated GHS information provided per 6906 reports by companies from 76 notifications to the ECHA C&L Inventory. Each notification may be associated with multiple companies.

Reported as not meeting GHS hazard criteria per 3 of 6906 reports by companies. For more detailed information, please visit ECHA C&L website.

There are 75 notifications provided by 6903 of 6906 reports by companies with hazard statement code(s).

Information may vary between notifications depending on impurities, additives, and other factors. The percentage value in parenthesis indicates the notified classification ratio from companies that provide hazard codes. Only hazard codes with percentage values above 10% are shown.

Met. Corr. 1 (47.3%)

Skin Corr. 1A (> 99.9%)

Eye Dam. 1 (43.8%)

Eye Irrit. 2 (36.7%)

Met. Corr. 1 (100%)

Skin Corr. 1B (100%)

Eye Dam. 1 (100%)

Chemical: Sodium hydroxide

· TOXIC and/or CORROSIVE; inhalation, ingestion or skin contact with material may cause severe injury or death.

· Contact with molten substance may cause severe burns to skin and eyes.

· Avoid any skin contact.

· Fire may produce irritating, corrosive and/or toxic gases.

· Runoff from fire control or dilution water may be corrosive and/or toxic and cause environmental contamination.

Excerpt from ERG Guide 154 [Substances - Toxic and/or Corrosive (Non-Combustible)]:

Non-combustible, substance itself does not burn but may decompose upon heating to produce corrosive and/or toxic fumes. Some are oxidizers and may ignite combustibles (wood, paper, oil, clothing, etc.). Corrosives in contact with metals may evolve flammable hydrogen gas. Containers may explode when heated. For electric vehicles or equipment, ERG Guide 147 (lithium ion or sodium ion batteries) or ERG Guide 138 (sodium batteries) should also be consulted. (ERG, 2024)

· Non-combustible, substance itself does not burn but may decompose upon heating to produce corrosive and/or toxic fumes.

· Some are oxidizers and may ignite combustibles (wood, paper, oil, clothing, etc.).

· Corrosives in contact with metals may evolve flammable hydrogen gas.

· Containers may explode when heated.

· For electric vehicles or equipment, GUIDE 147 (lithium ion or sodium ion batteries) or GUIDE 138 (sodium batteries) should also be consulted.

(Act quickly)

EYES: flush with water at once for at least 15 min.

SKIN: flush with water, then rinse with dilute vinegar (acetic acid).

INGESTION: give water and milk. Do NOT induce vomiting. Call physician at once, even when injury seems to be slight. (USCG, 1999)

Excerpt from NIOSH Pocket Guide for Sodium hydroxide:

Eye: IRRIGATE IMMEDIATELY - If this chemical contacts the eyes, immediately wash (irrigate) the eyes with large amounts of water, occasionally lifting the lower and upper lids. Get medical attention immediately.

Skin: WATER FLUSH IMMEDIATELY - If this chemical contacts the skin, immediately flush the contaminated skin with water. If this chemical penetrates the clothing, immediately remove the clothing and flush the skin with water. Get medical attention promptly.

Breathing: RESPIRATORY SUPPORT - If a person breathes large amounts of this chemical, move the exposed person to fresh air at once. If breathing has stopped, perform artificial respiration. Keep the affected person warm and at rest. Get medical attention as soon as possible.

Swallow: MEDICAL ATTENTION IMMEDIATELY - If this chemical has been swallowed, get medical attention immediately. (NIOSH, 2024)

General First Aid:

· Call 911 or emergency medical service.

· Ensure that medical personnel are aware of the material(s) involved, take precautions to protect themselves and avoid contamination.

· Move victim to fresh air if it can be done safely.

· Administer oxygen if breathing is difficult.

· If victim is not breathing:

-- DO NOT perform mouth-to-mouth resuscitation; the victim may have ingestedor inhaled the substance.

-- If equipped and pulse detected, wash face and mouth, then give artificial respiration using a proper respiratory medical device (bag-valve mask, pocket mask equipped with a one-way valve or other device).

-- If no pulse detected or no respiratory medical device available, provide continuouscompressions. Conduct a pulse check every two minutes or monitor for any signs of spontaneous respirations.

· Remove and isolate contaminated clothing and shoes.

· For minor skin contact, avoid spreading material on unaffected skin.

· In case of contact with substance, remove immediately by flushing skin or eyes with running water for at least 20 minutes.

· For severe burns, immediate medical attention is required.

· Effects of exposure (inhalation, ingestion, or skin contact) to substance may be delayed.

· Keep victim calm and warm.

· Keep victim under observation.

· For further assistance, contact your local Poison Control Center.

· Note: Basic Life Support (BLS) and Advanced Life Support (ALS) should be done by trained professionals.

Specific First Aid:

· For corrosives, in case of contact, immediately flush skin or eyes with running water for at least 30 minutes. Additional flushing may be required.

In Canada, an Emergency Response Assistance Plan (ERAP) may be required for this product. Please consult the shipping paper and/or the "ERAP" section.

(See general first aid procedures)

Eye: Irrigate immediately - If this chemical contacts the eyes, immediately wash (irrigate) the eyes with large amounts of water, occasionally lifting the lower and upper lids. Get medical attention immediately.

Skin: Water flush immediately - If this chemical contacts the skin, immediately flush the contaminated skin with water. If this chemical penetrates the clothing, immediately remove the clothing and flush the skin with water. Get medical attention promptly.

Breathing: Respiratory support

Swallow: Medical attention immediately - If this chemical has been swallowed, get medical attention immediately.

Excerpt from ERG Guide 154 [Substances - Toxic and/or Corrosive (Non-Combustible)]:

SMALL FIRE: Dry chemical, CO2 or water spray.

LARGE FIRE: Dry chemical, CO2, alcohol-resistant foam or water spray. If it can be done safely, move undamaged containers away from the area around the fire. Dike runoff from fire control for later disposal.

FIRE INVOLVING TANKS, RAIL TANK CARS OR HIGHWAY TANKS: Fight fire from maximum distance or use unmanned master stream devices or monitor nozzles. Do not get water inside containers. Cool containers with flooding quantities of water until well after fire is out. Withdraw immediately in case of rising sound from venting safety devices or discoloration of tank. ALWAYS stay away from tanks in direct contact with flames. (ERG, 2024)

· CALL 911. Then call emergency response telephone number on shipping paper. If shipping paper not available or no answer, refer to appropriate telephone number listed on the inside back cover.

· Keep unauthorized personnel away.

· Stay upwind, uphill and/or upstream.

· Ventilate closed spaces before entering, but only if properly trained and equipped.

· ELIMINATE all ignition sources (no smoking, flares, sparks or flames) from immediate area.

· Do not touch damaged containers or spilled material unless wearing appropriate protective clothing.

· Stop leak if you can do it without risk.

· Prevent entry into waterways, sewers, basements or confined areas.

· Absorb or cover with dry earth, sand or other non-combustible material and transfer to containers.

· DO NOT GET WATER INSIDE CONTAINERS.

Excerpt from ERG Guide 154 [Substances - Toxic and/or Corrosive (Non-Combustible)]:

IMMEDIATE PRECAUTIONARY MEASURE: Isolate spill or leak area in all directions for at least 50 meters (150 feet) for liquids and at least 25 meters (75 feet) for solids.

SPILL: Increase the immediate precautionary measure distance, in the downwind direction, as necessary.

FIRE: If tank, rail tank car or highway tank is involved in a fire, ISOLATE for 800 meters (1/2 mile) in all directions; also, consider initial evacuation for 800 meters (1/2 mile) in all directions. (ERG, 2024)

Immediate precautionary measure

· Isolate spill or leak area in all directions for at least 50 meters (150 feet) for liquids and at least 25 meters (75 feet) for solids.

Spill

· For highlighted materials: see Table 1 - Initial Isolation and Protective Action Distances.

· For non-highlighted materials: increase the immediate precautionary measure distance, in the downwind direction, as necessary.

Fire

· If tank, rail tank car or highway tank is involved in a fire, ISOLATE for 800 meters (1/2 mile) in all directions; also, consider initial evacuation for 800 meters (1/2 mile) in all directions.

Excerpt from ERG Guide 154 [Substances - Toxic and/or Corrosive (Non-Combustible)]:

ELIMINATE all ignition sources (no smoking, flares, sparks or flames) from immediate area. Do not touch damaged containers or spilled material unless wearing appropriate protective clothing. Stop leak if you can do it without risk. Prevent entry into waterways, sewers, basements or confined areas. Absorb or cover with dry earth, sand or other non-combustible material and transfer to containers. DO NOT GET WATER INSIDE CONTAINERS. (ERG, 2024)

· Wear positive pressure self-contained breathing apparatus (SCBA).

· Wear chemical protective clothing that is specifically recommended by the manufacturer when there is NO RISK OF FIRE.

· Structural firefighters' protective clothing provides thermal protection but only limited chemical protection.

10.0 [mg/m3]

Excerpts from Documentation for IDLHs: Human data: Workplace concentrations ranging from 2 to 8 mg/m3 have been associated with irritation of the respiratory system [Ott et al. 1977].

10 mg/m3

See: 1310732

Small Fire

· Dry chemical, CO2 or water spray.

Large Fire

· Dry chemical, CO2, alcohol-resistant foam or water spray.

· If it can be done safely, move undamaged containers away from the area around the fire.

· Dike runoff from fire control for later disposal.

Fire Involving Tanks, Rail Tank Cars or Highway Tanks

· Fight fire from maximum distance or use unmanned master stream devices or monitor nozzles.

· Do not get water inside containers.

· Cool containers with flooding quantities of water until well after fire is out.

· Withdraw immediately in case of rising sound from venting safety devices or discoloration of tank.

· ALWAYS stay away from tanks in direct contact with flames.

ERPG-1: 0.5 mg/m3 - one hour exposure limit: 1 = mild transient health effects or objectionable odor [AIHA]

ERPG-2: 5 mg/m3 - one hour exposure limit: 2 = impaired ability to take protective action [AIHA]

ERPG-3: 50 mg/m3 - one hour exposure limit: 3 = life threatening health effects [AIHA]

Excerpt from NIOSH Pocket Guide for Sodium hydroxide:

Skin: PREVENT SKIN CONTACT - Wear appropriate personal protective clothing to prevent skin contact.

Eyes: PREVENT EYE CONTACT - Wear appropriate eye protection to prevent eye contact.

Wash skin: WHEN CONTAMINATED - The worker should immediately wash the skin when it becomes contaminated.

Remove: WHEN WET OR CONTAMINATED - Work clothing that becomes wet or significantly contaminated should be removed and replaced.

Change: DAILY - Workers whose clothing may have become contaminated should change into uncontaminated clothing before leaving the work premises.

Provide:

• EYEWASH - Eyewash fountains should be provided in areas where there is any possibility that workers could be exposed to the substances; this is irrespective of the recommendation involving the wearing of eye protection.

• QUICK DRENCH - Facilities for quickly drenching the body should be provided within the immediate work area for emergency use where there is a possibility of exposure. [Note: It is intended that these facilities provide a sufficient quantity or flow of water to quickly remove the substance from any body areas likely to be exposed. The actual determination of what constitutes an adequate quick drench facility depends on the specific circumstances. In certain instances, a deluge shower should be readily available, whereas in others, the availability of water from a sink or hose could be considered adequate.] (NIOSH, 2024)

(See personal protection and sanitation codes)

Skin: Prevent skin contact - Wear appropriate personal protective clothing to prevent skin contact.

Eyes: Prevent eye contact - Wear appropriate eye protection to prevent eye contact.

Wash skin: When contaminated

Remove: When wet or contaminated

Change: Daily - Workers whose clothing may have become contaminated should change into uncontaminated clothing before leaving the work premises.

Provide: Eyewash, Quick drench

NIOSH/OSHA

Up to 10 mg/m3 :

(APF = 25) Any supplied-air respirator operated in a continuous-flow mode/

(APF = 50) Any air-purifying, full-facepiece respirator with an N100, R100, or P100 filter.

Click here for information on selection of N, R, or P filters.

(APF = 25) Any powered, air-purifying respirator with a high-efficiency particulate filter.

(APF = 50) Any self-contained breathing apparatus with a full facepiece

(APF = 50) Any supplied-air respirator with a full facepiece

Emergency or planned entry into unknown concentrations or IDLH conditions:

(APF = 10,000) Any self-contained breathing apparatus that has a full facepiece and is operated in a pressure-demand or other positive-pressure mode

(APF = 10,000) Any supplied-air respirator that has a full facepiece and is operated in a pressure-demand or other positive-pressure mode in combination with an auxiliary self-contained positive-pressure breathing apparatus

Escape:

(APF = 50) Any air-purifying, full-facepiece respirator with an N100, R100, or P100 filter.

Click here for information on selection of N, R, or P filters.

Any appropriate escape-type, self-contained breathing apparatus

Bases, Strong

Water and Aqueous Solutions

Hazard Traits - Dermatotoxicity; Ocular Toxicity; Respiratory Toxicity

Authoritative List - OEHHA RELs

Report - if used as a fragrance or flavor ingredient

Status: Active Update: 13-07-2021 https://echa.europa.eu/registration-dossier/-/registered-dossier/24304

Status: Active Update: 11-05-2023 https://echa.europa.eu/registration-dossier/-/registered-dossier/15566

Status: Cease Manufacture Update: 29-05-2013 https://echa.europa.eu/registration-dossier/-/registered-dossier/7515

IMAP assessments - Sodium hydroxide (Na(OH)): Environment tier I assessment

IMAP assessments - Sodium hydroxide: Human health tier II assessment

Dermatotoxin - Skin burns.

Toxic Pneumonitis - Inflammation of the lungs induced by inhalation of metal fumes or toxic gases and vapors.

Patents are available for this chemical structure:

https://patentscope.wipo.int/search/en/result.jsf?inchikey=HEMHJVSKTPXQMS-UHFFFAOYSA-M

Patents are available for this chemical structure:

https://patentscope.wipo.int/search/en/result.jsf?inchikey=MIFHFHTXOFFMGY-UHFFFAOYSA-N

- Agency for Toxic Substances and Disease Registry (ATSDR)LICENSEThe information provided using CDC Web site is only intended to be general summary information to the public. It is not intended to take the place of either the written law or regulations.https://www.cdc.gov/Other/disclaimer.htmlSodium Hydroxidehttps://wwwn.cdc.gov/TSP/substances/ToxSubstance.aspx?toxid=45

- Haz-Map, Information on Hazardous Chemicals and Occupational DiseasesLICENSECopyright (c) 2022 Haz-Map(R). All rights reserved. Unless otherwise indicated, all materials from Haz-Map are copyrighted by Haz-Map(R). No part of these materials, either text or image may be used for any purpose other than for personal use. Therefore, reproduction, modification, storage in a retrieval system or retransmission, in any form or by any means, electronic, mechanical or otherwise, for reasons other than personal use, is strictly prohibited without prior written permission.https://haz-map.com/AboutSodium hydroxidehttps://haz-map.com/Agents/628

- CAMEO ChemicalsLICENSECAMEO Chemicals and all other CAMEO products are available at no charge to those organizations and individuals (recipients) responsible for the safe handling of chemicals. However, some of the chemical data itself is subject to the copyright restrictions of the companies or organizations that provided the data.https://cameochemicals.noaa.gov/help/reference/terms_and_conditions.htm?d_f=falseSODIUM HYDROXIDE SOLUTIONhttps://cameochemicals.noaa.gov/chemical/1499SODIUM HYDROXIDE, SOLIDhttps://cameochemicals.noaa.gov/chemical/9073CAMEO Chemical Reactivity Classificationhttps://cameochemicals.noaa.gov/browse/react

- ChEBISodium hydroxidehttps://www.ebi.ac.uk/chebi/searchId.do?chebiId=CHEBI:32145

- DrugBankLICENSECreative Common's Attribution-NonCommercial 4.0 International License (http://creativecommons.org/licenses/by-nc/4.0/legalcode)https://www.drugbank.ca/legal/terms_of_useSodium hydroxidehttps://www.drugbank.ca/drugs/DB11151

- Australian Industrial Chemicals Introduction Scheme (AICIS)Sodium hydroxide (Na(OH))https://services.industrialchemicals.gov.au/search-assessments/Sodium hydroxide (Na(OH))https://services.industrialchemicals.gov.au/search-inventory/

- CAS Common ChemistryLICENSEThe data from CAS Common Chemistry is provided under a CC-BY-NC 4.0 license, unless otherwise stated.https://creativecommons.org/licenses/by-nc/4.0/Sodium hydroxidehttps://commonchemistry.cas.org/detail?cas_rn=1310-73-2

- ChemIDplusSodium hydroxide [NF]https://pubchem.ncbi.nlm.nih.gov/substance/?source=chemidplus&sourceid=0001310732ChemIDplus Chemical Information Classificationhttps://pubchem.ncbi.nlm.nih.gov/source/ChemIDplus

- DTP/NCILICENSEUnless otherwise indicated, all text within NCI products is free of copyright and may be reused without our permission. Credit the National Cancer Institute as the source.https://www.cancer.gov/policies/copyright-reuse

- EPA Chemical Data Reporting (CDR)LICENSEThe U.S. Government retains a nonexclusive, royalty-free license to publish or reproduce these documents, or allow others to do so, for U.S. Government purposes. These documents may be freely distributed and used for non-commercial, scientific and educational purposes.https://www.epa.gov/web-policies-and-procedures/epa-disclaimers#copyrightSodium hydroxide (Na(OH))https://www.epa.gov/chemical-data-reporting

- EPA Chemicals under the TSCASodium hydroxide (Na(OH))https://www.epa.gov/chemicals-under-tscaEPA TSCA Classificationhttps://www.epa.gov/tsca-inventory

- EPA DSSToxSodium hydroxidehttps://comptox.epa.gov/dashboard/DTXSID0029634CompTox Chemicals Dashboard Chemical Listshttps://comptox.epa.gov/dashboard/chemical-lists/

- European Chemicals Agency (ECHA)LICENSEUse of the information, documents and data from the ECHA website is subject to the terms and conditions of this Legal Notice, and subject to other binding limitations provided for under applicable law, the information, documents and data made available on the ECHA website may be reproduced, distributed and/or used, totally or in part, for non-commercial purposes provided that ECHA is acknowledged as the source: "Source: European Chemicals Agency, http://echa.europa.eu/". Such acknowledgement must be included in each copy of the material. ECHA permits and encourages organisations and individuals to create links to the ECHA website under the following cumulative conditions: Links can only be made to webpages that provide a link to the Legal Notice page.https://echa.europa.eu/web/guest/legal-noticeSodium hydroxidehttps://chem.echa.europa.eu/100.013.805Sodium hydroxide (EC: 215-185-5)https://echa.europa.eu/information-on-chemicals/cl-inventory-database/-/discli/details/134413Ascarite (EC: 688-015-4)https://echa.europa.eu/information-on-chemicals/cl-inventory-database/-/discli/details/219535

- FDA Global Substance Registration System (GSRS)LICENSEUnless otherwise noted, the contents of the FDA website (www.fda.gov), both text and graphics, are not copyrighted. They are in the public domain and may be republished, reprinted and otherwise used freely by anyone without the need to obtain permission from FDA. Credit to the U.S. Food and Drug Administration as the source is appreciated but not required.https://www.fda.gov/about-fda/about-website/website-policies#linkingSodium hydroxidehttps://gsrs.ncats.nih.gov/ginas/app/beta/substances/55X04QC32I

- Hazardous Substances Data Bank (HSDB)SODIUM HYDROXIDEhttps://pubchem.ncbi.nlm.nih.gov/source/hsdb/229

- ILO-WHO International Chemical Safety Cards (ICSCs)

- International Fragrance Association (IFRA)LICENSE(c) The International Fragrance Association, 2007-2021. All rights reserved.https://ifrafragrance.org/links/copyright

- New Zealand Environmental Protection Authority (EPA)LICENSEThis work is licensed under the Creative Commons Attribution-ShareAlike 4.0 International licence.https://www.epa.govt.nz/about-this-site/general-copyright-statement/

- NJDOH RTK Hazardous Substance Listsodium hydroxidehttp://nj.gov/health/eoh/rtkweb/documents/fs/1706.pdf

- Occupational Safety and Health Administration (OSHA)LICENSEMaterials created by the federal government are generally part of the public domain and may be used, reproduced and distributed without permission. Therefore, content on this website which is in the public domain may be used without the prior permission of the U.S. Department of Labor (DOL). Warning: Some content - including both images and text - may be the copyrighted property of others and used by the DOL under a license.https://www.dol.gov/general/aboutdol/copyrightSODIUM HYDROXIDEhttps://www.osha.gov/chemicaldata/211

- Risk Assessment Information System (RAIS)LICENSEThis work has been sponsored by the U.S. Department of Energy (DOE), Office of Environmental Management, Oak Ridge Operations (ORO) Office through a joint collaboration between United Cleanup Oak Ridge LLC (UCOR), Oak Ridge National Laboratory (ORNL), and The University of Tennessee, Ecology and Evolutionary Biology, The Institute for Environmental Modeling (TIEM). All rights reserved.https://rais.ornl.gov/Sodium Hydroxidehttps://rais.ornl.gov/cgi-bin/tools/TOX_search

- EU Food Improvement AgentsSODIUM HYDROXIDEhttp://data.europa.eu/eli/reg/2012/231/2024-04-23

- California Safe Cosmetics Program (CSCP) Product DatabaseSodium hydroxidehttps://cscpsearch.cdph.ca.gov/search/detailresult/3136

- EU Pesticides Database

- Consumer Product Information Database (CPID)LICENSECopyright (c) 2024 DeLima Associates. All rights reserved. Unless otherwise indicated, all materials from CPID are copyrighted by DeLima Associates. No part of these materials, either text or image may be used for any purpose other than for personal use. Therefore, reproduction, modification, storage in a retrieval system or retransmission, in any form or by any means, electronic, mechanical or otherwise, for reasons other than personal use, is strictly prohibited without prior written permission.https://www.whatsinproducts.com/contents/view/1/6Sodium hydroxidehttps://www.whatsinproducts.com/chemicals/view/1/19/001310-73-2Consumer Products Category Classificationhttps://www.whatsinproducts.com/

- Cosmetic Ingredient Review (CIR)

- NORMAN Suspect List ExchangeLICENSEData: CC-BY 4.0; Code (hosted by ECI, LCSB): Artistic-2.0https://creativecommons.org/licenses/by/4.0/Sodium HydroxideNORMAN Suspect List Exchange Classificationhttps://www.norman-network.com/nds/SLE/

- Emergency Response Guidebook (ERG)Sodium hydroxidehttps://pubchem.ncbi.nlm.nih.gov/erg/

- The National Institute for Occupational Safety and Health (NIOSH)LICENSEThe information provided using CDC Web site is only intended to be general summary information to the public. It is not intended to take the place of either the written law or regulations.https://www.cdc.gov/Other/disclaimer.htmlSodium hydroxidehttps://www.cdc.gov/niosh/npg/npgd0565.htmlSodium hydroxidehttps://www.cdc.gov/niosh-rtecs/WB4AC4A0.html

- ChEMBLLICENSEAccess to the web interface of ChEMBL is made under the EBI's Terms of Use (http://www.ebi.ac.uk/Information/termsofuse.html). The ChEMBL data is made available on a Creative Commons Attribution-Share Alike 3.0 Unported License (http://creativecommons.org/licenses/by-sa/3.0/).http://www.ebi.ac.uk/Information/termsofuse.html

- Comparative Toxicogenomics Database (CTD)LICENSEIt is to be used only for research and educational purposes. Any reproduction or use for commercial purpose is prohibited without the prior express written permission of NC State University.http://ctdbase.org/about/legal.jspSodium Hydroxidehttps://ctdbase.org/detail.go?type=chem&acc=D012972

- EPA Chemical and Products Database (CPDat)EPA CPDat Classificationhttps://www.epa.gov/chemical-research/chemical-and-products-database-cpdat

- Crystallography Open Database (COD)LICENSEAll data in the COD and the database itself are dedicated to the public domain and licensed under the CC0 License. Users of the data should acknowledge the original authors of the structural data.https://creativecommons.org/publicdomain/zero/1.0/

- DailyMed

- EPA Safer ChoiceSodium hydroxidehttps://www.epa.gov/saferchoice/safer-ingredientsEPA Safer Chemical Ingredients Classificationhttps://www.epa.gov/saferchoice

- Joint FAO/WHO Expert Committee on Food Additives (JECFA)LICENSEPermission from WHO is not required for the use of WHO materials issued under the Creative Commons Attribution-NonCommercial-ShareAlike 3.0 Intergovernmental Organization (CC BY-NC-SA 3.0 IGO) licence.https://www.who.int/about/policies/publishing/copyright

- Hazardous Chemical Information System (HCIS), Safe Work Australia

- NITE-CMCSodium hydroxide - FY2009 (Revised classification)https://www.chem-info.nite.go.jp/chem/english/ghs/09-mhlw-2010e.htmlSodium hydroxide - FY2006 (New/original classication)https://www.chem-info.nite.go.jp/chem/english/ghs/06-imcg-0592e.html

- Regulation (EC) No 1272/2008 of the European Parliament and of the CouncilLICENSEThe copyright for the editorial content of this source, the summaries of EU legislation and the consolidated texts, which is owned by the EU, is licensed under the Creative Commons Attribution 4.0 International licence.https://eur-lex.europa.eu/content/legal-notice/legal-notice.htmlsodium hydroxide; caustic sodahttps://eur-lex.europa.eu/eli/reg/2008/1272/oj

- FDA Substances Added to FoodLICENSEUnless otherwise noted, the contents of the FDA website (www.fda.gov), both text and graphics, are not copyrighted. They are in the public domain and may be republished, reprinted and otherwise used freely by anyone without the need to obtain permission from FDA. Credit to the U.S. Food and Drug Administration as the source is appreciated but not required.https://www.fda.gov/about-fda/about-website/website-policies#linking

- Human Metabolome Database (HMDB)LICENSEHMDB is offered to the public as a freely available resource. Use and re-distribution of the data, in whole or in part, for commercial purposes requires explicit permission of the authors and explicit acknowledgment of the source material (HMDB) and the original publication (see the HMDB citing page). We ask that users who download significant portions of the database cite the HMDB paper in any resulting publications.http://www.hmdb.ca/citingSodium hydroxide (NaOH)http://www.hmdb.ca/metabolites/HMDB0303523

- Japan Chemical Substance Dictionary (Nikkaji)

- KEGGLICENSEAcademic users may freely use the KEGG website. Non-academic use of KEGG generally requires a commercial licensehttps://www.kegg.jp/kegg/legal.htmlTherapeutic category of drugs in Japanhttp://www.genome.jp/kegg-bin/get_htext?br08301.kegDrugs listed in the Japanese Pharmacopoeiahttp://www.genome.jp/kegg-bin/get_htext?br08311.keg

- National Drug Code (NDC) DirectoryLICENSEUnless otherwise noted, the contents of the FDA website (www.fda.gov), both text and graphics, are not copyrighted. They are in the public domain and may be republished, reprinted and otherwise used freely by anyone without the need to obtain permission from FDA. Credit to the U.S. Food and Drug Administration as the source is appreciated but not required.https://www.fda.gov/about-fda/about-website/website-policies#linking

- NCI Thesaurus (NCIt)LICENSEUnless otherwise indicated, all text within NCI products is free of copyright and may be reused without our permission. Credit the National Cancer Institute as the source.https://www.cancer.gov/policies/copyright-reuseNCI Thesaurushttps://ncit.nci.nih.gov

- NIOSH Manual of Analytical MethodsLICENSEThe information provided using CDC Web site is only intended to be general summary information to the public. It is not intended to take the place of either the written law or regulations.https://www.cdc.gov/Other/disclaimer.html

- NLM RxNorm TerminologyLICENSEThe RxNorm Terminology is created by the National Library of Medicine (NLM) and is in the public domain and may be republished, reprinted and otherwise used freely by anyone without the need to obtain permission from NLM. Credit to the U.S. National Library of Medicine as the source is appreciated but not required. The full RxNorm dataset requires a free license.https://www.nlm.nih.gov/research/umls/rxnorm/docs/termsofservice.htmlsodium hydroxidehttps://rxnav.nlm.nih.gov/id/rxnorm/9880

- Pistoia Alliance Chemical Safety LibraryMETHANOL + 5-METHYLISOXAZOLE + SODIUM HYDROXIDEhttps://safescience.cas.org/

- SpectraBaseSodium hydroxidehttps://spectrabase.com/spectrum/2qe0C1Yik8K

- Springer Nature

- SpringerMaterialssodium hydroxidehttps://materials.springer.com/substance/111915/sodium_hydroxide

- Thieme ChemistryLICENSEThe Thieme Chemistry contribution within PubChem is provided under a CC-BY-NC-ND 4.0 license, unless otherwise stated.https://creativecommons.org/licenses/by-nc-nd/4.0/

- Wikidatasodium hydroxidehttps://www.wikidata.org/wiki/Q102769

- Wikipediasodium hydroxidehttps://en.wikipedia.org/wiki/Sodium_hydroxide

- Wiley

- Medical Subject Headings (MeSH)LICENSEWorks produced by the U.S. government are not subject to copyright protection in the United States. Any such works found on National Library of Medicine (NLM) Web sites may be freely used or reproduced without permission in the U.S.https://www.nlm.nih.gov/copyright.htmlSodium Hydroxidehttps://www.ncbi.nlm.nih.gov/mesh/68012972

- PubChem

- GHS Classification (UNECE)GHS Classification Treehttp://www.unece.org/trans/danger/publi/ghs/ghs_welcome_e.html

- EPA Substance Registry ServicesEPA SRS List Classificationhttps://sor.epa.gov/sor_internet/registry/substreg/LandingPage.do

- MolGenieMolGenie Organic Chemistry Ontologyhttps://github.com/MolGenie/ontology/

- PATENTSCOPE (WIPO)SID 403029312https://pubchem.ncbi.nlm.nih.gov/substance/403029312SID 403349085https://pubchem.ncbi.nlm.nih.gov/substance/403349085

CID 962 (Water)

CID 962 (Water) CID 5360545 (Sodium)

CID 5360545 (Sodium)