Dibutyl ether

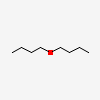

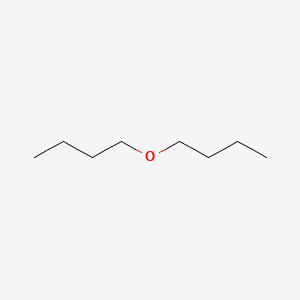

- C8H18O

- (CH3CH2CH2CH2)2O

- Butyl ether

- DIBUTYL ETHER

- Di-n-butyl ether

- 142-96-1

- 1-Butoxybutane

- Create:2005-03-26

- Modify:2025-01-11

C8H18O

(CH3CH2CH2CH2)2O

- Butyl ether

- DIBUTYL ETHER

- Di-n-butyl ether

- 142-96-1

- 1-Butoxybutane

- Butane, 1,1'-oxybis-

- n-Butyl ether

- Dibutyl oxide

- Butyl oxide

- Ether butylique

- di-n-butylether

- 1,1'-Oxybis(butane)

- 1,1'-oxydibutane

- n-Dibutyl ether

- CCRIS 6010

- HSDB 306

- 1-Butoxy-butane

- UNII-PBM2R52P5G

- NSC 8459

- EINECS 205-575-3

- BRN 1732752

- 1,1'-Oxybisbutane

- (n-C4H9)2O

- DTXSID1022007

- AI3-00402

- NSC-8459

- N-BUTYL ETHER [MI]

- PBM2R52P5G

- DIBUTYL ETHER [HSDB]

- DTXCID002007

- EC 205-575-3

- 4-01-00-01520 (Beilstein Handbook Reference)

- UN 1149

- Ether butylique [French]

- 5-Oxanonane

- DIBUTYL ETHER (NORMAL) (BUTYL ETHER)

- DIBUTYL ETHER (NORMAL) {BUTYL ETHER}

- butylether

- butyloxide

- dibutylether

- dibutyloxide

- n-butylether

- 1Butoxybutane

- Dinbutyl ether

- nDibutyl ether

- di n-butylether

- din butyl ether

- di-n butyl ether

- di-1-butyl ether

- nBu2O

- di(1-butyl) ether

- MFCD00009461

- UN1149

- Butane,1'-oxybis-

- di-n-butyl, ether-

- Butyl ether (8CI)

- Bu2O

- BUTYL ETHERS

- n-Bu2O

- 1,1'Oxybis(butane)

- Butane, 1,1'oxybis

- Di-(1-butyl) ether

- 1-BUTOXY BUTANE

- SCHEMBL15167

- CHEMBL48132

- Dibutyl ether, p.a., 99%

- WLN: 4O4

- NSC8459

- Dibutyl ether, anhydrous, 99.3%

- (C4H9)2O

- Tox21_201037

- STL280282

- AKOS015915425

- Dibutyl ether, ReagentPlus(R), >=99%

- NCGC00248903-01

- NCGC00258590-01

- CAS-142-96-1

- Dibutyl ether, purum, >=99.0% (GC)

- LS-13538

- B0721

- NS00004547

- EN300-315383

- A807991

- J-007726

- J-520373

- Q1207808

- F0001-0501

- Activity

- Azeotropes

- Boiling point

- Chemical diffusion

- Chemical shift

- Composition

- Compressibility

- Corrosion

- Density

- Dielectric constant

- Diffusion

- Diffusive flux

- Excess enthalpy

- Excess volume

- Heat capacity

- Heat of solution

- Heat of sublimation

- Latent heat

- Lineshape

- Mixing enthalpy

- Optical coefficient

- Phase diagram

- Phase equilibrium

- Refractive index

- Solid-liquid phase equilibrium

- Sound velocity

- Surface tension

- Thermal conductivity

- Thermal expansion coefficient

- Vapor pressure

- Vapor-liquid equilibrium

- Virial coefficient

- Viscosity

57 99.99

41 37.86

29 26.73

56 15.03

87 12.33

57 99.99

87 18

56 16.40

41 12.80

29 6.40

57 999

41 313

29 268

87 168

56 165

- Intermediate

- Intermediates

Information on 2 consumer products that contain Butyl ether in the following categories is provided:

• Home Maintenance

Information on 1 consumer products that contain Dibutyl ether in the following categories is provided:

• Home Maintenance

2019: 1,000,000 lb - <20,000,000 lb

2018: 1,000,000 lb - <20,000,000 lb

2017: 1,000,000 lb - <20,000,000 lb

2016: 1,000,000 lb - <20,000,000 lb

- All Other Basic Organic Chemical Manufacturing

- Miscellaneous Manufacturing

H226 (99.9%): Flammable liquid and vapor [Warning Flammable liquids]

H315 (100%): Causes skin irritation [Warning Skin corrosion/irritation]

H319 (100%): Causes serious eye irritation [Warning Serious eye damage/eye irritation]

H335 (100%): May cause respiratory irritation [Warning Specific target organ toxicity, single exposure; Respiratory tract irritation]

H412 (99.9%): Harmful to aquatic life with long lasting effects [Hazardous to the aquatic environment, long-term hazard]

P210, P233, P240, P241, P242, P243, P261, P264, P264+P265, P271, P273, P280, P302+P352, P303+P361+P353, P304+P340, P305+P351+P338, P319, P321, P332+P317, P337+P317, P362+P364, P370+P378, P403+P233, P403+P235, P405, and P501

(The corresponding statement to each P-code can be found at the GHS Classification page.)

Aggregated GHS information provided per 1348 reports by companies from 24 notifications to the ECHA C&L Inventory. Each notification may be associated with multiple companies.

Information may vary between notifications depending on impurities, additives, and other factors. The percentage value in parenthesis indicates the notified classification ratio from companies that provide hazard codes. Only hazard codes with percentage values above 10% are shown.

Flam. Liq. 3 (99.9%)

Skin Irrit. 2 (100%)

Eye Irrit. 2 (100%)

STOT SE 3 (100%)

Aquatic Chronic 3 (99.9%)

Flammable liquid - category 3

Eye irritation - category 2

Specific target organ toxicity (single exposure) - category 3

Skin irritation - category 2

Hazardous to the aquatic environment (chronic) - category 3

CAUTION: Petroleum crude oil (UN1267) may contain TOXIC hydrogen sulphide gas.

· Inhalation or contact with material may irritate or burn skin and eyes.

· Fire may produce irritating, corrosive and/or toxic gases.

· Vapors may cause dizziness or asphyxiation, especially when in closed or confined areas.

· Runoff from fire control or dilution water may cause environmental contamination.

· HIGHLY FLAMMABLE: Will be easily ignited by heat, sparks or flames.

· Vapors may form explosive mixtures with air.

· Vapors may travel to source of ignition and flash back.

· Most vapors are heavier than air. They will spread along the ground and collect in low or confined areas (sewers, basements, tanks, etc.).

· Vapor explosion hazard indoors, outdoors or in sewers.

· Those substances designated with a (P) may polymerize explosively when heated or involved in a fire.

· Runoff to sewer may create fire or explosion hazard.

· Containers may explode when heated.

· Many liquids will float on water.

· Substance may be transported hot.

· For hybrid vehicles, GUIDE 147 (lithium ion or sodium ion batteries) or GUIDE 138 (sodium batteries) should also be consulted.

· If molten aluminum is involved, refer to GUIDE 169.

EYES: First check the victim for contact lenses and remove if present. Flush victim's eyes with water or normal saline solution for 20 to 30 minutes while simultaneously calling a hospital or poison control center. Do not put any ointments, oils, or medication in the victim's eyes without specific instructions from a physician. IMMEDIATELY transport the victim after flushing eyes to a hospital even if no symptoms (such as redness or irritation) develop.

SKIN: IMMEDIATELY flood affected skin with water while removing and isolating all contaminated clothing. Gently wash all affected skin areas thoroughly with soap and water. If symptoms such as redness or irritation develop, IMMEDIATELY call a physician and be prepared to transport the victim to a hospital for treatment.

INHALATION: IMMEDIATELY leave the contaminated area; take deep breaths of fresh air. If symptoms (such as wheezing, coughing, shortness of breath, or burning in the mouth, throat, or chest) develop, call a physician and be prepared to transport the victim to a hospital. Provide proper respiratory protection to rescuers entering an unknown atmosphere. Whenever possible, Self-Contained Breathing Apparatus (SCBA) should be used; if not available, use a level of protection greater than or equal to that advised under Protective Clothing.

INGESTION: DO NOT INDUCE VOMITING. If the victim is conscious and not convulsing, give 1 or 2 glasses of water to dilute the chemical and IMMEDIATELY call a hospital or poison control center. Be prepared to transport the victim to a hospital if advised by a physician. If the victim is convulsing or unconscious, do not give anything by mouth, ensure that the victim's airway is open and lay the victim on his/her side with the head lower than the body. DO NOT INDUCE VOMITING. IMMEDIATELY transport the victim to a hospital. (NTP, 1992)

General First Aid:

· Call 911 or emergency medical service.

· Ensure that medical personnel are aware of the material(s) involved, take precautions to protect themselves and avoid contamination.

· Move victim to fresh air if it can be done safely.

· Administer oxygen if breathing is difficult.

· If victim is not breathing:

-- DO NOT perform mouth-to-mouth resuscitation; the victim may have ingestedor inhaled the substance.

-- If equipped and pulse detected, wash face and mouth, then give artificial respiration using a proper respiratory medical device (bag-valve mask, pocket mask equipped with a one-way valve or other device).

-- If no pulse detected or no respiratory medical device available, provide continuouscompressions. Conduct a pulse check every two minutes or monitor for any signs of spontaneous respirations.

· Remove and isolate contaminated clothing and shoes.

· For minor skin contact, avoid spreading material on unaffected skin.

· In case of contact with substance, remove immediately by flushing skin or eyes with running water for at least 20 minutes.

· For severe burns, immediate medical attention is required.

· Effects of exposure (inhalation, ingestion, or skin contact) to substance may be delayed.

· Keep victim calm and warm.

· Keep victim under observation.

· For further assistance, contact your local Poison Control Center.

· Note: Basic Life Support (BLS) and Advanced Life Support (ALS) should be done by trained professionals.

Specific First Aid:

· Wash skin with soap and water.

· In case of burns, immediately cool affected skin for as long as possible with cold water. Do not remove clothing if adhering to skin.

In Canada, an Emergency Response Assistance Plan (ERAP) may be required for this product. Please consult the shipping paper and/or the "ERAP" section.

Excerpt from ERG Guide 128 [Flammable Liquids (Water-Immiscible)]:

CAUTION: The majority of these products have a very low flash point. Use of water spray when fighting fire may be inefficient. CAUTION: For mixtures containing alcohol or polar solvent, alcohol-resistant foam may be more effective.

SMALL FIRE: Dry chemical, CO2, water spray or regular foam. If regular foam is ineffective or unavailable, use alcohol-resistant foam.

LARGE FIRE: Water spray, fog or regular foam. If regular foam is ineffective or unavailable, use alcohol-resistant foam. Avoid aiming straight or solid streams directly onto the product. If it can be done safely, move undamaged containers away from the area around the fire.

FIRE INVOLVING TANKS, RAIL TANK CARS OR HIGHWAY TANKS: Fight fire from maximum distance or use unmanned master stream devices or monitor nozzles. Cool containers with flooding quantities of water until well after fire is out. For petroleum crude oil, do not spray water directly into a breached tank car. This can lead to a dangerous boil over. Withdraw immediately in case of rising sound from venting safety devices or discoloration of tank. ALWAYS stay away from tanks in direct contact with flames. For massive fire, use unmanned master stream devices or monitor nozzles; if this is impossible, withdraw from area and let fire burn. (ERG, 2024)

· CALL 911. Then call emergency response telephone number on shipping paper. If shipping paper not available or no answer, refer to appropriate telephone number listed on the inside back cover.

· Keep unauthorized personnel away.

· Stay upwind, uphill and/or upstream.

· Ventilate closed spaces before entering, but only if properly trained and equipped.

· ELIMINATE all ignition sources (no smoking, flares, sparks or flames) from immediate area.

· All equipment used when handling the product must be grounded.

· Do not touch or walk through spilled material.

· Stop leak if you can do it without risk.

· Prevent entry into waterways, sewers, basements or confined areas.

· A vapor-suppressing foam may be used to reduce vapors.

· Absorb or cover with dry earth, sand or other non-combustible material and transfer to containers.

· Use clean, non-sparking tools to collect absorbed material.

Large Spill

· Dike far ahead of liquid spill for later disposal.

· Water spray may reduce vapor, but may not prevent ignition in closed spaces.

Excerpt from ERG Guide 128 [Flammable Liquids (Water-Immiscible)]:

IMMEDIATE PRECAUTIONARY MEASURE: Isolate spill or leak area for at least 50 meters (150 feet) in all directions.

LARGE SPILL: Consider initial downwind evacuation for at least 300 meters (1000 feet).

FIRE: If tank, rail tank car or highway tank is involved in a fire, ISOLATE for 800 meters (1/2 mile) in all directions; also, consider initial evacuation for 800 meters (1/2 mile) in all directions. (ERG, 2024)

Immediate precautionary measure

· Isolate spill or leak area for at least 50 meters (150 feet) in all directions.

Large Spill

· Consider initial downwind evacuation for at least 300 meters (1000 feet).

Fire

· If tank, rail tank car or highway tank is involved in a fire, ISOLATE for 800 meters (1/2 mile) in all directions; also, consider initial evacuation for 800 meters (1/2 mile) in all directions.

Excerpt from ERG Guide 128 [Flammable Liquids (Water-Immiscible)]:

ELIMINATE all ignition sources (no smoking, flares, sparks or flames) from immediate area. All equipment used when handling the product must be grounded. Do not touch or walk through spilled material. Stop leak if you can do it without risk. Prevent entry into waterways, sewers, basements or confined areas. A vapor-suppressing foam may be used to reduce vapors. Absorb or cover with dry earth, sand or other non-combustible material and transfer to containers. Use clean, non-sparking tools to collect absorbed material.

LARGE SPILL: Dike far ahead of liquid spill for later disposal. Water spray may reduce vapor, but may not prevent ignition in closed spaces. (ERG, 2024)

· Wear positive pressure self-contained breathing apparatus (SCBA).

· Structural firefighters' protective clothing provides thermal protection but only limited chemical protection.

CAUTION: The majority of these products have a very low flash point. Use of water spray when fighting fire may be inefficient.

CAUTION: For mixtures containing alcohol or polar solvent, alcohol-resistant foam may be more effective.

Small Fire

· Dry chemical, CO2, water spray or regular foam. If regular foam is ineffective or unavailable, use alcohol-resistant foam.

Large Fire

· Water spray, fog or regular foam. If regular foam is ineffective or unavailable, use alcohol-resistant foam.

· Avoid aiming straight or solid streams directly onto the product.

· If it can be done safely, move undamaged containers away from the area around the fire.

Fire Involving Tanks, Rail Tank Cars or Highway Tanks

· Fight fire from maximum distance or use unmanned master stream devices or monitor nozzles.

· Cool containers with flooding quantities of water until well after fire is out.

· For petroleum crude oil, do not spray water directly into a breached tank car. This can lead to a dangerous boil over.

· Withdraw immediately in case of rising sound from venting safety devices or discoloration of tank.

· ALWAYS stay away from tanks in direct contact with flames.

· For massive fire, use unmanned master stream devices or monitor nozzles; if this is impossible, withdraw from area and let fire burn.

Highly Flammable

Peroxidizable Compound

Dasler,W.etal.,Ind.Eng.Chem.(Anal.Ed.),1946,18,52

Kirk-Othmer Encyclopedia of Chemical Technology. 3rd ed., Volumes 1-26. New York, NY: John Wiley and Sons, 1978-1984., p. V17: 48

Sax, N.I. and R.J. Lewis, Sr. (eds.). Hawley's Condensed Chemical Dictionary. 11th ed. New York: Van Nostrand Reinhold Co., 1987., p. 186

Neurotoxin - Acute solvent syndrome

Occupational hepatotoxin - Secondary hepatotoxins: the potential for toxic effect in the occupational setting is based on cases of poisoning by human ingestion or animal experimentation.

Patents are available for this chemical structure:

https://patentscope.wipo.int/search/en/result.jsf?inchikey=DURPTKYDGMDSBL-UHFFFAOYSA-N

- Australian Industrial Chemicals Introduction Scheme (AICIS)Butane, 1,1'-oxybis-https://services.industrialchemicals.gov.au/search-inventory/

- CAMEO ChemicalsLICENSECAMEO Chemicals and all other CAMEO products are available at no charge to those organizations and individuals (recipients) responsible for the safe handling of chemicals. However, some of the chemical data itself is subject to the copyright restrictions of the companies or organizations that provided the data.https://cameochemicals.noaa.gov/help/reference/terms_and_conditions.htm?d_f=falseN-BUTYL ETHERhttps://cameochemicals.noaa.gov/chemical/281CAMEO Chemical Reactivity Classificationhttps://cameochemicals.noaa.gov/browse/react

- ILO-WHO International Chemical Safety Cards (ICSCs)

- CAS Common ChemistryLICENSEThe data from CAS Common Chemistry is provided under a CC-BY-NC 4.0 license, unless otherwise stated.https://creativecommons.org/licenses/by-nc/4.0/

- ChemIDplusChemIDplus Chemical Information Classificationhttps://pubchem.ncbi.nlm.nih.gov/source/ChemIDplus

- DTP/NCILICENSEUnless otherwise indicated, all text within NCI products is free of copyright and may be reused without our permission. Credit the National Cancer Institute as the source.https://www.cancer.gov/policies/copyright-reuse

- EPA Chemical Data Reporting (CDR)LICENSEThe U.S. Government retains a nonexclusive, royalty-free license to publish or reproduce these documents, or allow others to do so, for U.S. Government purposes. These documents may be freely distributed and used for non-commercial, scientific and educational purposes.https://www.epa.gov/web-policies-and-procedures/epa-disclaimers#copyrightButane, 1,1'-oxybis-https://www.epa.gov/chemical-data-reporting

- EPA Chemicals under the TSCAButane, 1,1'-oxybis-https://www.epa.gov/chemicals-under-tscaEPA TSCA Classificationhttps://www.epa.gov/tsca-inventory

- EPA DSSToxCompTox Chemicals Dashboard Chemical Listshttps://comptox.epa.gov/dashboard/chemical-lists/

- European Chemicals Agency (ECHA)LICENSEUse of the information, documents and data from the ECHA website is subject to the terms and conditions of this Legal Notice, and subject to other binding limitations provided for under applicable law, the information, documents and data made available on the ECHA website may be reproduced, distributed and/or used, totally or in part, for non-commercial purposes provided that ECHA is acknowledged as the source: "Source: European Chemicals Agency, http://echa.europa.eu/". Such acknowledgement must be included in each copy of the material. ECHA permits and encourages organisations and individuals to create links to the ECHA website under the following cumulative conditions: Links can only be made to webpages that provide a link to the Legal Notice page.https://echa.europa.eu/web/guest/legal-noticeDibutyl etherhttps://chem.echa.europa.eu/100.005.069Dibutyl ether (EC: 205-575-3)https://echa.europa.eu/information-on-chemicals/cl-inventory-database/-/discli/details/130866

- FDA Global Substance Registration System (GSRS)LICENSEUnless otherwise noted, the contents of the FDA website (www.fda.gov), both text and graphics, are not copyrighted. They are in the public domain and may be republished, reprinted and otherwise used freely by anyone without the need to obtain permission from FDA. Credit to the U.S. Food and Drug Administration as the source is appreciated but not required.https://www.fda.gov/about-fda/about-website/website-policies#linking

- Hazardous Substances Data Bank (HSDB)DIBUTYL ETHERhttps://pubchem.ncbi.nlm.nih.gov/source/hsdb/306

- New Zealand Environmental Protection Authority (EPA)LICENSEThis work is licensed under the Creative Commons Attribution-ShareAlike 4.0 International licence.https://www.epa.govt.nz/about-this-site/general-copyright-statement/

- NJDOH RTK Hazardous Substance List

- Emergency Response Guidebook (ERG)Butyl ethershttps://pubchem.ncbi.nlm.nih.gov/erg/

- Haz-Map, Information on Hazardous Chemicals and Occupational DiseasesLICENSECopyright (c) 2022 Haz-Map(R). All rights reserved. Unless otherwise indicated, all materials from Haz-Map are copyrighted by Haz-Map(R). No part of these materials, either text or image may be used for any purpose other than for personal use. Therefore, reproduction, modification, storage in a retrieval system or retransmission, in any form or by any means, electronic, mechanical or otherwise, for reasons other than personal use, is strictly prohibited without prior written permission.https://haz-map.com/Aboutn-Butyl etherhttps://haz-map.com/Agents/8265

- ChEMBLLICENSEAccess to the web interface of ChEMBL is made under the EBI's Terms of Use (http://www.ebi.ac.uk/Information/termsofuse.html). The ChEMBL data is made available on a Creative Commons Attribution-Share Alike 3.0 Unported License (http://creativecommons.org/licenses/by-sa/3.0/).http://www.ebi.ac.uk/Information/termsofuse.html

- Consumer Product Information Database (CPID)LICENSECopyright (c) 2024 DeLima Associates. All rights reserved. Unless otherwise indicated, all materials from CPID are copyrighted by DeLima Associates. No part of these materials, either text or image may be used for any purpose other than for personal use. Therefore, reproduction, modification, storage in a retrieval system or retransmission, in any form or by any means, electronic, mechanical or otherwise, for reasons other than personal use, is strictly prohibited without prior written permission.https://www.whatsinproducts.com/contents/view/1/6Consumer Products Category Classificationhttps://www.whatsinproducts.com/

- Crystallography Open Database (COD)LICENSEAll data in the COD and the database itself are dedicated to the public domain and licensed under the CC0 License. Users of the data should acknowledge the original authors of the structural data.https://creativecommons.org/publicdomain/zero/1.0/

- EPA Chemical and Products Database (CPDat)EPA CPDat Classificationhttps://www.epa.gov/chemical-research/chemical-and-products-database-cpdat

- Hazardous Chemical Information System (HCIS), Safe Work Australia

- NITE-CMCdi-n-butyl ether; dibutyl ether - FY2008 (New/original classication)https://www.chem-info.nite.go.jp/chem/english/ghs/08-mhlw-0198e.html

- Regulation (EC) No 1272/2008 of the European Parliament and of the CouncilLICENSEThe copyright for the editorial content of this source, the summaries of EU legislation and the consolidated texts, which is owned by the EU, is licensed under the Creative Commons Attribution 4.0 International licence.https://eur-lex.europa.eu/content/legal-notice/legal-notice.htmldi-n-butyl ether; dibutyl etherhttps://eur-lex.europa.eu/eli/reg/2008/1272/oj

- NMRShiftDB

- MassBank Europe

- IUPAC Digitized pKa Datasetdi-n-butyl, ether-https://github.com/IUPAC/Dissociation-Constants

- Japan Chemical Substance Dictionary (Nikkaji)

- KNApSAcK Species-Metabolite Database

- Natural Product Activity and Species Source (NPASS)

- Lab and Research Safety, University of MinnesotaDibutyl ether

- MassBank of North America (MoNA)LICENSEThe content of the MoNA database is licensed under CC BY 4.0.https://mona.fiehnlab.ucdavis.edu/documentation/license

- NIST Mass Spectrometry Data CenterLICENSEData covered by the Standard Reference Data Act of 1968 as amended.https://www.nist.gov/srd/public-lawn-Butyl etherhttp://www.nist.gov/srd/nist1a.cfm

- SpectraBaseBUTANE, 1,1'-OXYBIS-https://spectrabase.com/spectrum/LgwSDrEY5GbDibutyletherhttps://spectrabase.com/spectrum/8H94uWMQZKCBUTYL ETHERhttps://spectrabase.com/spectrum/ASSxFYyR5YIbutyl etherhttps://spectrabase.com/spectrum/7ukNWx9ujJJBUTYL ETHERhttps://spectrabase.com/spectrum/Di5mlwncZD6BUTANE, 1,1'-OXYBIS-https://spectrabase.com/spectrum/8eQlFBI7RWtButyl etherhttps://spectrabase.com/spectrum/JAMZ6wLFykzDibutyl etherhttps://spectrabase.com/spectrum/GX2DtA2109bButane, 1,1'-oxybis-https://spectrabase.com/spectrum/Gu9MDJBk8A4Butane, 1,1'-oxybis-https://spectrabase.com/spectrum/9ZYsC2rRaRtButane, 1,1'-oxybis-https://spectrabase.com/spectrum/Gdf45iuZncwDibutyl etherhttps://spectrabase.com/spectrum/G2KkEykDbD0Butane, 1,1'-oxybis-https://spectrabase.com/spectrum/FCgqIAaJPOKButane, 1,1'-oxybis-https://spectrabase.com/spectrum/EI31w14AJBhDibutyl etherhttps://spectrabase.com/spectrum/2avImVieCEP

- Metabolomics Workbench

- Springer Nature

- SpringerMaterials

- Thieme ChemistryLICENSEThe Thieme Chemistry contribution within PubChem is provided under a CC-BY-NC-ND 4.0 license, unless otherwise stated.https://creativecommons.org/licenses/by-nc-nd/4.0/

- Wikidatabutyl etherhttps://www.wikidata.org/wiki/Q1207808

- WikipediaCycloheptenehttps://en.wikipedia.org/wiki/CyclohepteneDibutyl etherhttps://en.wikipedia.org/wiki/Dibutyl_ether

- Wiley

- PubChem

- Medical Subject Headings (MeSH)LICENSEWorks produced by the U.S. government are not subject to copyright protection in the United States. Any such works found on National Library of Medicine (NLM) Web sites may be freely used or reproduced without permission in the U.S.https://www.nlm.nih.gov/copyright.htmldibutyl etherhttps://www.ncbi.nlm.nih.gov/mesh/67053284

- GHS Classification (UNECE)GHS Classification Treehttp://www.unece.org/trans/danger/publi/ghs/ghs_welcome_e.html

- NORMAN Suspect List ExchangeLICENSEData: CC-BY 4.0; Code (hosted by ECI, LCSB): Artistic-2.0https://creativecommons.org/licenses/by/4.0/NORMAN Suspect List Exchange Classificationhttps://www.norman-network.com/nds/SLE/

- EPA Substance Registry ServicesEPA SRS List Classificationhttps://sor.epa.gov/sor_internet/registry/substreg/LandingPage.do

- MolGenieMolGenie Organic Chemistry Ontologyhttps://github.com/MolGenie/ontology/

- PATENTSCOPE (WIPO)SID 403032077https://pubchem.ncbi.nlm.nih.gov/substance/403032077